But the quantity of types of CNC machines are there? In the following sections, I provide a wide overview of each and every type of CNC machine.

You may well be utilizing another gadget or browser when compared to the a person you originally activated. Just re-enter your electronic mail within the re-verify webpage, and also you’ll see our pricing.

A 3D printer is actually a type of CNC machine that creates a few-dimensional workpieces by incorporating the material layer by layer, dependant on a digital design or design.

cnc precision machining Let’s get started with what on earth is CNC machining initially. It can be a pc-controlled machining process that routinely eliminates materials based on uploaded design and electronic Guidance. The automation in tool movement presents tighter tolerance than regular machining strategies.

Their Production-On-Demand production philosophy makes certain that all turning centers are equipped with the most recent technology to boost productivity and support organization growth.

The Okuma Genos L400 will come with numerous options for customization. These can incorporate Increased spindles, additional tool turrets, and advanced software packages for far better control and diagnostics.

The mechanism of CNC drilling entails a rotating drill bit and stationery workpiece. Because the drill bit penetrates the surface area, it cuts and OKUMA CNC lathe suppliers chips absent the material from your drilling spot to create a gap. The drill bits are precisely the same dimension since the diameter of the specified hole.

This setup is perfect for parts that need machining on both finishes. Through the use of dual spindles, it is possible to lower setup situations and enhance production fees.

Bar feeders automate the feeding of bar stock to the lathe, permitting for constant Procedure. This is certainly essential for high-volume production.

GSK CNC Machines Co., Ltd. (hereinafter referred as GSK) is specifically devoted to conducting exploration and observe of essential products industrial enhancement, supplying "trinity" packaged solutions of machine tool CNC system, servo drive and servo motor, using initiative inside the expansion of industrial robot and all-electric powered injection molding machine subject, establishing The brand new marketing manner of machine tool exhibition corridor, furnishing the customers with all-round professional machine tool remanufacturing solutions and services, selling the integration of production and education and learning, setting up the vocational education and learning and training institute, as well as conducting highly experienced CNC staff training.

Adjusting the CNC machining variables and tooling setup makes it possible for us to support several products, from really hard titanium grades to comfortable aluminum and plastics.

While the two are types of CNC lathes, a Swiss lathe and a standard CNC lathe have important variations in how they support the workpiece and accomplish cuts.

One of several standout features of CNC lathes is their high diploma of automation. At the time programmed, these machines can run with nominal human intervention. This lessens labor charges and minimizes human mistake.

Common Turning Centers: In a typical CNC lathe, the workpiece is held by a chuck or collet at a single stop. The cutting tool moves along the workpiece to accomplish the machining operations. This setup is best suited to shorter, bulkier parts.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Heather Locklear Then & Now!

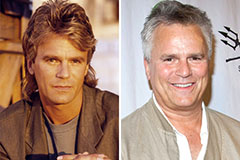

Heather Locklear Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!